Glass has special properties. For example, it is transparent, chemically inert, an electrical insulator, gas-tight, resistant to temperature fluctuations, a radiation filter and non magnetic. Depending on the specific requirements and wishes, it can be the best or sometimes the only option.

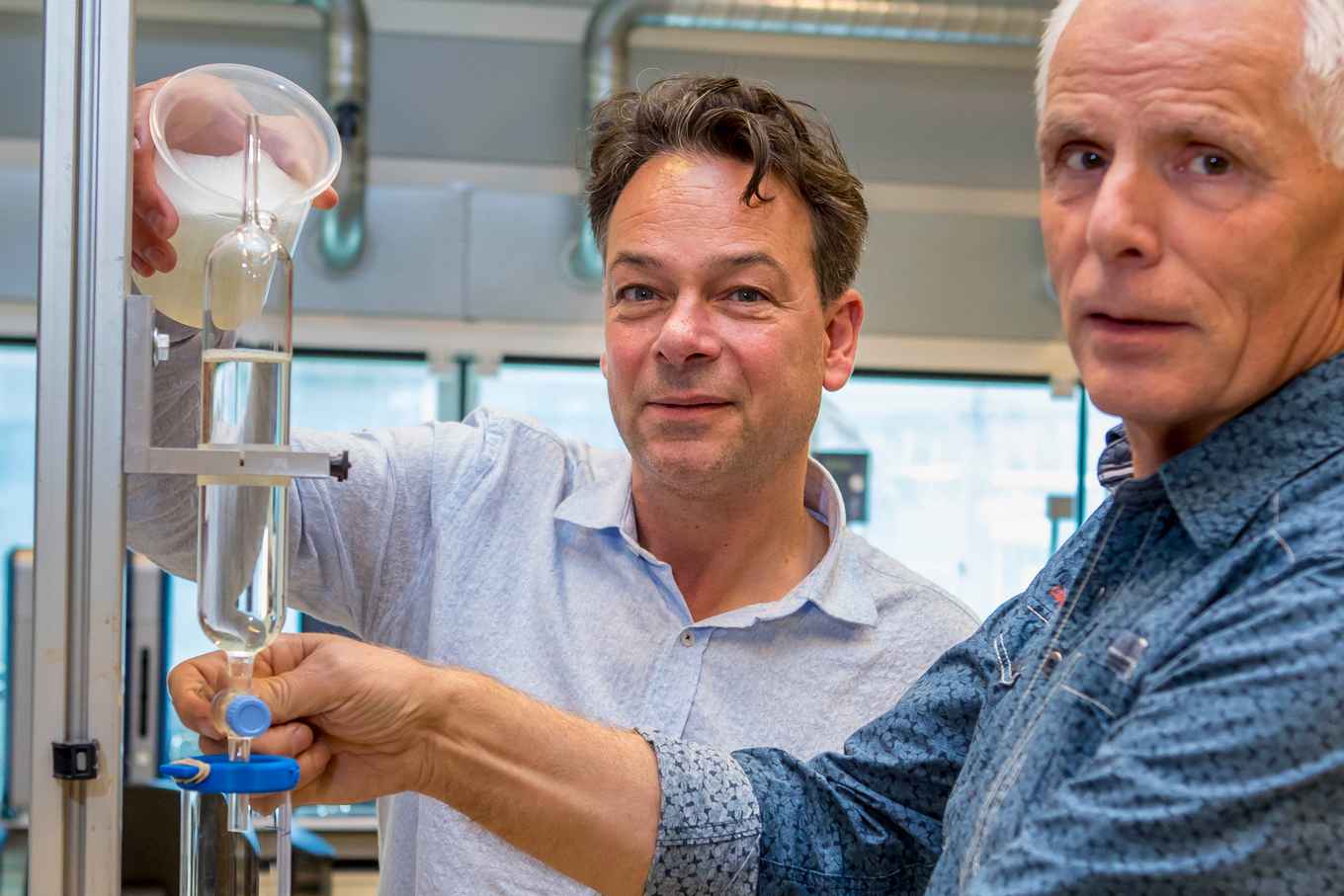

The Glass Instrument Workshop develops and produces custom-made glass instruments, optical components and configurations, and delivers solutions for glass engineering issues. It also modifies existing configurations and instruments and carries out repairs.

The newest innovation is 3D-printing of quartz glass and 2D-machining of complex contours in glass with a waterjet and laser welding of embedding metals like platina, gold and silver.

The Glass Instrument Workshop uses the following techniques:

- Hot working of borosilicate and quartz glass

- Cold working (cylindrical grinding, sawing, drilling and surface grinding) of any type of glass and technical ceramics (Al2O3), makor and silicon carbide, etc. using diamond tools

- Cylindrical griding of screw threads and spiral grooves for quartz and ceramic oven tubes

- Stretching capillaries to a thickness of 0.08 mm

- Vacuum soldering for optical glass without deformation

- Connection techniques like (UV-)adhesive and glass-metal constructions

- Using melting to embed samples in quartz or borosilicate glass with the addition of a protective gas

We can also assist in obtaining non-standard optical components such as prisms, mirrors and lenses. And we are experienced in giving advice on the various applications of coatings (AR, high reflection, filters).

Because of its transparency, glass is also extremely suitable as a demonstration aid and as a model. Due to its formability and graceful properties, glass is also a beautiful material for awards and parting gifts.